Supply Chain 360

Key to organizational resilience

For decades, lean supply chain management has been the norm for most organizations. Lean dates back to the 1940s when Toyota launched its groundbreaking Toyota Production System, a just-in-time approach to manufacturing and logistics.

It’s not an exaggeration to say that Toyota revolutionized the way we do business internationally and accelerated globalization. But ironically, because of our global interconnectedness, organizations are now exposed to risks throughout their supply chain.

Multiple simultaneous shocks to the system can have a cascading effect on business operations, leading to delays, shortages, and skyrocketing costs. We first saw this in 2008 during the global financial crisis and again in 2020 at the beginning of the Covid-19 pandemic.

Understandably, organizations want their supply chains to become resilient to external shocks and internal dynamics, such as shifting business strategies. Yet, despite this goal of resilience, most organizations still struggle with being proactive regarding their supply chains. Instead, they continue to operate in a reactive mode while using an outdated approach to supply chain management.

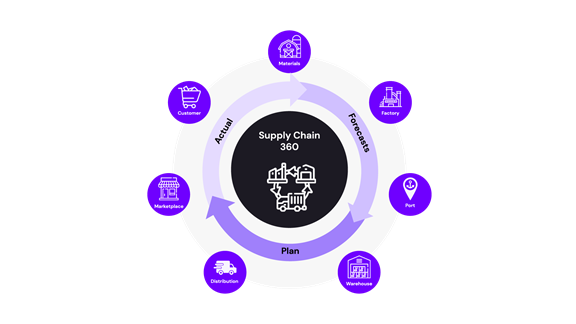

The solution is to switch the playbook for supply chain management from Lean to a “Supply Chain 360” approach, which is a circular system with data availability, transparency, insights, and information gleaned from that data shared up and down the chain.

This modern approach will yield greater financial rewards because your organization will operate in an environment where resiliency and risk pose greater downsides and upsides than the continuous cost reduction of everyday business.