Amazon’s Dash buttons have drawn a lot of attention since they were unveiled in 2015 in the US. The premise is simple: the buttons aim to remove the arduous task of reordering household items by placing small buttons all over your home. One in the bathroom for toothpaste, and one in the kitchen for cat food... another in the kitchen for washing up liquid. Oh, and another for dishwasher tablets...

...Wait a minute. It doesn’t seem very frictionless, does it? Or even convenient, for that matter. Surely consumers would prefer a solution that doesn’t lock them in, and doesn’t need a proliferation of different buttons for all of the different consumer products that a household gets through in a week?

And is ‘easy reordering’ enough of an incentive for consumers to stick branded buttons all over their houses? What’s more, relying on the actual friction of a physical button press to reorder products seems curiously clunky when compared to the ‘no-UI is the ultimate UI’ trends in product and service design.

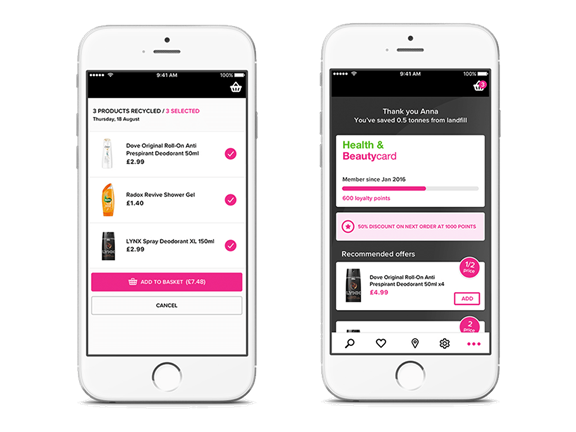

When an FMCG client asked us recently to participate in a hackathon, challenging teams to make reordering day-to-day products a friction-free, planet-saving experience, we saw an exciting opportunity to investigate and prototype a different approach to the Dash buttons.

Instead of physical buttons, we wanted to explore the ways in which sensors could offer a better way forward - particularly when integrated with loyalty schemes.